The metal plating process has been used to preserve and add beauty.

Traditional wet electroplating of brass, gold, and nickel finishes require clear coats that are routinely degraded by solar radiation and can easily tarnish or corrode.

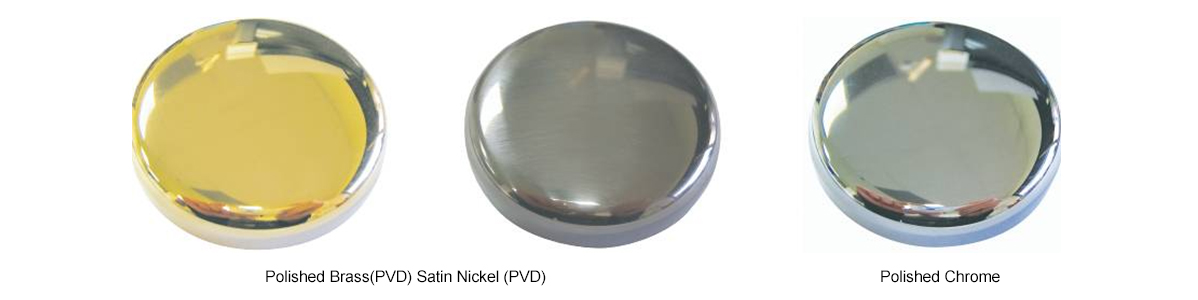

PVD is a method of vaporizing, ionizing, and depositing high purity metals and gases onto components in a vacuum chamber to achi eve metal compounds that look like brass, gold, and nickel.

An electric arc is used to evaporate and ionize base metals, while reactive gases flow into the chamber. Together they form very hard, dense metal compounds on the parts.

PVD deposits metals in a vacuum chamber. It is a dry process with environmentally compliant technology. PVD coatings representthe revolution in decorative metal finish.